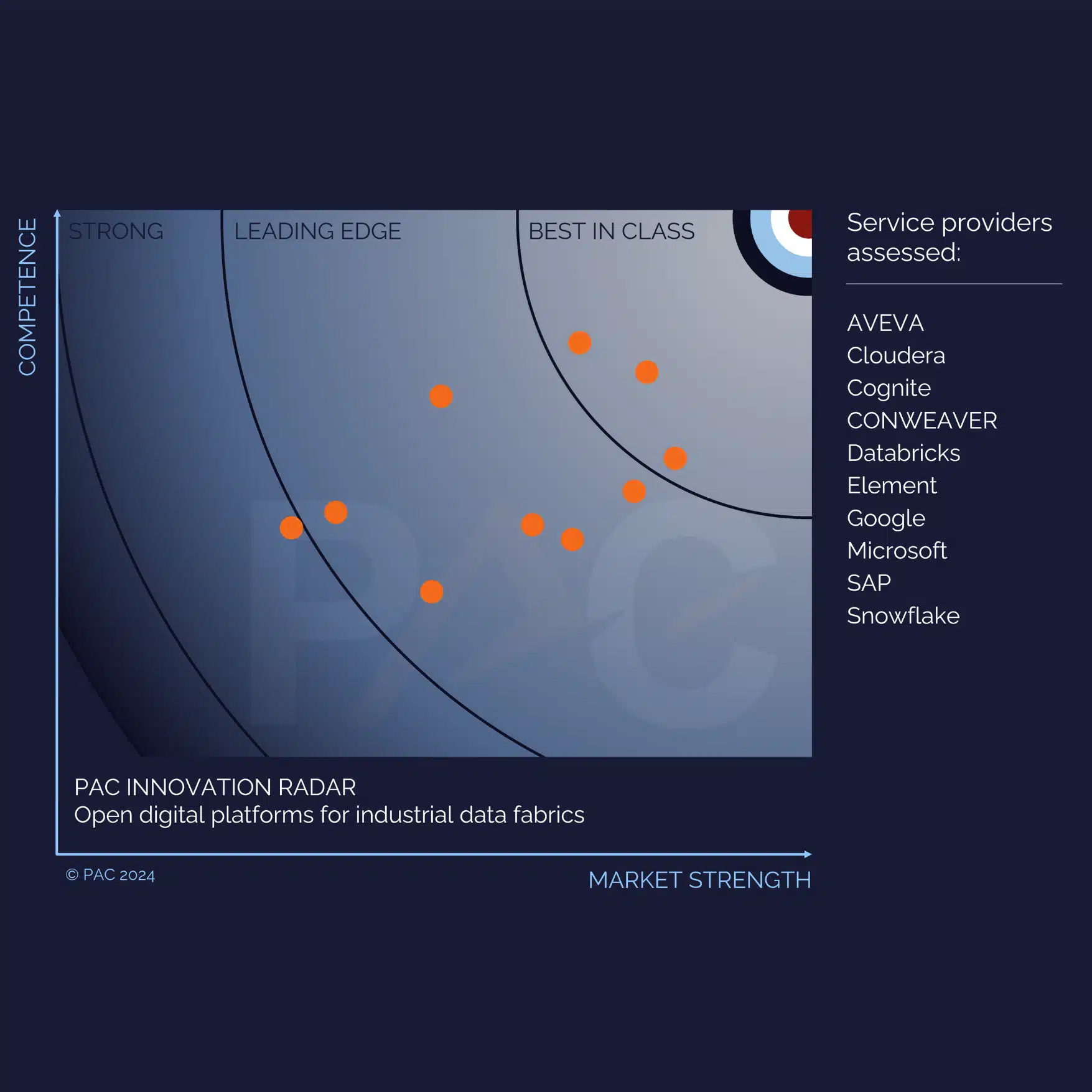

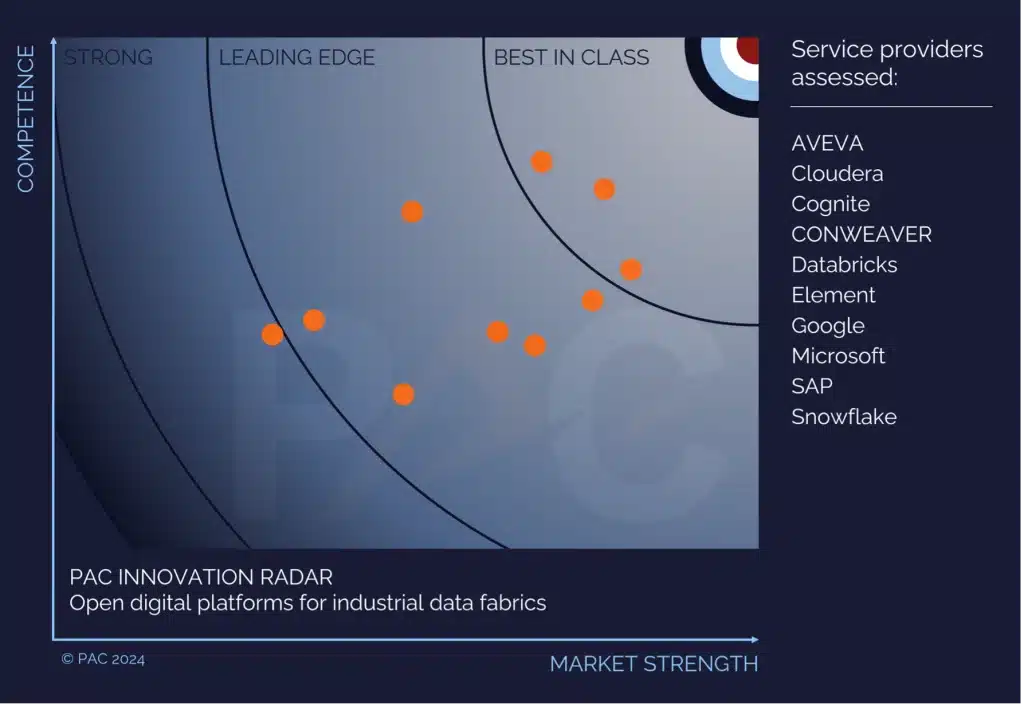

Munich, July 25, 2024 – Market research and strategic consulting firm PAC presents its six-part PAC INNOVATION RADAR “Open Digital Platforms for the Industrial World in Europe 2024.” It is the most comprehensive analysis of the vendor landscape for open digital platforms for use in industrial contexts. In six RADAR segments, PAC reviews around 120 platforms and evaluates 77 of them in the European market. Across all segments, only 12 players achieved a “Best in Class” rating – German Edge Cloud, Phoenix Contact, PTC, Siemens, and TeamViewer, to name but a few.

PAC annually evaluates the vendor landscape around open digital platforms for industrial purposes in the European market. The focus of the RADAR analyses lies on differentiating between different platform concepts and evaluating new emerging topics. The 2024 launch of the Open Digital Platform for the Industrial World in Europe Innovation RADAR adds two emerging topics to the evaluation – industrial copilots (GenAI) and industrial data fabrics.

Evaluation of innovative platform concepts – industrial edge management, connected worker, industrial metaverse, and smart logistics services

Industrial edge management – These platforms use new concepts from the IT world, such as container technology and app store models, to simplify application lifecycle management at the industrial edge (OT world). Machine builders use this concept to provide smart digital services around industrial machinery and equipment. A continuously growing vendor landscape underpins the relevance of these platforms.

“Platforms help to handle the increasing digital complexity and simplify IT management at scale in times of IT skills shortage. Consequently, edge management platforms are helpful tools for many manufacturing companies,” says Arnold Vogt, Head of Digital & IoT at PAC.

Connected worker – These platforms provide visual guidance and support to industrial workers. Relevant use cases include visual step-by-step instructions, visual remote expert support, visually-guided failure recognition, and quality checks. The topic is currently going through a consolidation and integration phase.

Industrial metaverse – The industrial metaverse has the ambition to bring visual process simulation of holistic industrial systems to the next level. The vision of the industrial metaverse is to combine visual process simulation of large and complex industrial systems with the user experience of computer games – with photo-realistic, collaborative, and intuitive interactions. This can be used to create a virtual reality and an immersive experience of complex industrial operations to better sell, plan, run, and learn. To have a solid starting point for this analysis, PAC started with a focus on existing plant simulation software vendors. Today, only limited progress can be seen in the realization of this vision.

Smart logistics services – These platforms contain a growing number of digital services to manage and optimize all aspects of logistics companies and freight forwarders. This especially includes sensor-based analytics services around vehicle fleets, trailers, drivers, warehouses, and logistics centers. In addition, these platforms act as an integration layer between different digital services and with existing transportation management systems.

“Platforms for smart logistics services have the ambition to push the digitization of many small logistics service providers, by radically simplifying the identification, buying, and integration process of new digital services,” says Arnold Vogt, Head of Digital & IoT at PAC.

Newly emerging topics – industrial copilots (GenAI) and industrial data fabrics

PAC is constantly analyzing new emerging topics, adding two more topics to its analysis in 2024:

Industrial copilots (GenAI) – These platforms give access to different generative AI-powered assistants (copilots) to enhance human-machine collaboration and to improve industrial productivity. Industrial copilots can, for example, help automation engineers to faster generate code for programmable logic controllers (PLC) via natural language inputs. Copilots can also explain code and create automated documentation. In addition, industrial copilots can have access to documentation, guidelines, and manuals to assist industrial workers in faster identifying relevant information. As the progress of GenAI-based industrial copilots is slower than initially expected, it was necessary to reduce the entry barriers to this early vendor evaluation.

Industrial data fabrics – Larger manufacturing companies are facing the challenge of collecting, integrating, and making effective use of large volumes of available data from different sources. Data fabrics are a promising concept to overcome data silos in IT and OT. The vision is to create a digitally integrated manufacturing company without data silos, with open data access, deep transparency across the company, user-specific and deep analytics capabilities, agile workflow development, and ever-increasing process automation. As we focus on multi-cloud data platform offerings for industrial use cases, we recognize that only a handful of vendors offer a manufacturing-related platform around the data fabrics concept today.“When data is the new oil, data fabrics are gas stations that democratize access to oil in a consumable way and prepare it for direct ingestion into data processing engines,” says Arnold Vogt, Head of Digital & IoT at PAC.

– one of six RADAR segments

More information on the PAC INNOVATION RADAR “Open Digital Platforms for the Industrial World in Europe 2024”: www.pac-radar.com